In the dynamic world of supply chain management, the importance of effective inventory management cannot be underestimated. One of the key components that play a crucial role in both the movement and holding of goods is platforms. These platform structures have become indispensable in warehouses, enabling smooth movement and arrangement of products. As businesses strive to enhance their operational efficiency, understanding the importance of dependable pallets becomes crucial.

Pallets serve as the cornerstone of logistical operations, providing a standardized method for handling and arranging goods. Their configuration allows for simple loading and unloading, whether by manually or with machinery, which greatly reduces the time and labor involved in inventory management. Moreover, using durable and properly made pallets ensures that products remain protected during transport and storage, preventing harm and loss. As we look closer into the world of inventory management, the role of pallets emerges as a fundamental element that can lead to significant improvements in efficiency and productivity.

Significance of Shipping Pallets in Stock Management

Shipping pallets play a essential role in inventory management by providing a robust and efficient means of moving and keeping goods. They facilitate easy movement of products within storage facilities and during transportation. With consistent sizes, pallets enable compatibility with various handling equipment, like loading machinery and pallet jacks, enhancing operational efficiency. This uniformity leads to faster loading and unloading processes, ultimately conserving time and lowering labor costs.

Using pallets also helps to better organization in warehousing. Items can be placed on pallets, maximizing vertical space and keeping products off the floor, which helps prevent injury and spoilage. This systematic approach allows for improved inventory visibility and accessibility, making it more convenient for staff to locate and manage stock. A efficiently arranged inventory system using pallets can substantially reduce the risk of inventory errors and loss.

In addition, pallets are key in preserving the integrity of products during transportation. Sturdy materials, such as timber or synthetics, provide strength and safeguarding against environmental factors. By securing goods on a pallet, companies can reduce the risk of damage from shifting during transit. This dependability not only keeps the quality of products but also boosts customer satisfaction, making pallets necessary for efficient inventory management.

Types of Pallets and Their Uses

Pallets come in different varieties, each intended for specific applications in the transportation and storage of products. The most frequently used type is the timber pallet, known for its resilience and robustness. These pallets are often used in distribution centers and transport sectors where heavy loads need to be moved effectively. Wooden pallets are generally simple to fix and can be repurposed, making them a popular choice for cost-effectiveness. However, they may be vulnerable to moisture, insect damage, or splintering if not well cared for.

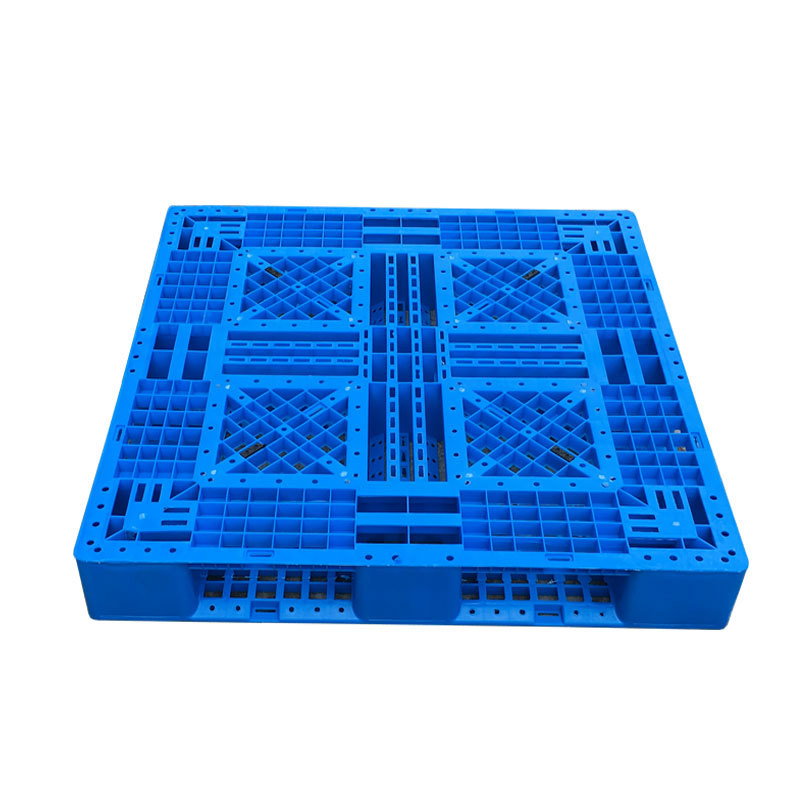

Another widely used type is the synthetic pallet, which offers several pros over wooden pallets. These pallets are protected against moisture, chemicals, and temperature fluctuations, making them ideal for fields such as healthcare and edible goods processing. Plastic pallets are lightweight, simple to sanitize, and often have a longer lifespan than their wooden counterparts. Their design usually features attributes that prevent slipping, ensuring safety during movement during transportation and storage.

Metal platforms, primarily made from iron or aluminum, are utilized in robust tasks where strength and durability are crucial. These pallets can handle significant pressure and are often used in fabrication and transport industries. While they tend to be costlier than wooden and plastic options, their extended lifespan and resistance to wear make them a valuable purchase for companies requiring strong options for transporting and storing substantial or toxic substances.

Optimal Practices for Pallet Stowing and Handling

Efficient pallet storage and handling is essential for upholding a smooth inventory management process. First, it is vital to assess the mass and size of the items being stored to opt for the appropriate pallet type that can handle the load. Using pallets that are too weak can lead to accidents and product damage. Routine inspections of pallets for any signs of damage or wear are critical to guarantee they are in good condition for safe use.

When storing pallets, orderliness is key. Creating a specific storage area for pallets keeps the workspace tidy and helps in rapidly locating pallets when needed. Implementing a first-in, first-out (FIFO) system can help in managing inventory successfully, especially for perishable goods. Additionally, stacking pallets in tulsa prevents tipping and reduces the risk of injuries in the workplace.

Managing pallets properly is equally important for efficiency. Use appropriate machinery like pallet jacks and forklifts to shift pallets, minimizing the risk of physical strain on workers. Train staff on the correct techniques for hoisting and maneuvering pallets to maintain safety standards. By sticking to these recommended practices, businesses can enhance their pallet management processes and enhance overall productivity.